Fax:0086-29-33698670

Email:sales@xagy.cn

Location:No. 88 East of Century Avenue, XianYang, Shaanxi, China. P.C. 712046

Control Expansion alloy ASTM F15 Kovar

Kovar (ASTM F15)-UNS K94610

Kovar alloy is a iron-nickel-cobalt, low expansion alloy whose chemical composition is controlled within narrow limits to assure precise uniform thermal expansion properties. Extensive quality controls are employed in the manufacture of this alloy to ensure uniform physical and mechanical properties for ease in deep drawing, stamping and machining.

Our production process for Kovar alloy is first melted using Vacuum Induction Melting (VIM) techniques. A secondary melt operation, Electro Slag Remelt (ESR), is then employed to further remove impurities and improve overall homogeneity.

Contact us for more information regarding our wide selection of controlled expansion Kovar products, Email: supportsales@xagy.cn OR call us at +86 29 3366 9103 and we will happily answer your questions regarding our tough and versatile Kovar alloy materials.

Chemical Conposition,Weight %

Max

Max

Max

Max

Max

Max

Max

Max

Max

Max

Physical Properties

Ni

Co

Si

Mn

C

Al

Mg

Zr

Ti

Cu

Cr

Mo

Fe

28.5-29.5

16.8-17.8

0.20

0.50

0.04

0.10

0.10

0.10

0.10

0.20

0.20

0.20

Bal.

- Specific Gravity: 8.36 g/cc

- Curie Temperature: 435℃ / 815℉

- Melting Point: 1450℃/ 2640℉

- Thermal Conductivity: 17.3 W/m ⋅ K

- Electrical Resistivity: 49 microhm/cm

Average Linear Coefficient of Thermal Expansion

30 to 400 ℃

30 to 450 ℃

Forms Manufactured

4.6 to 5.2 µm/m -°C

5.1 to 5.5 µm/m -°C

|

|

|

|

|

|

Kovar Rod |

Kovar plate |

|

|

|

|

Kovar Sheet

|

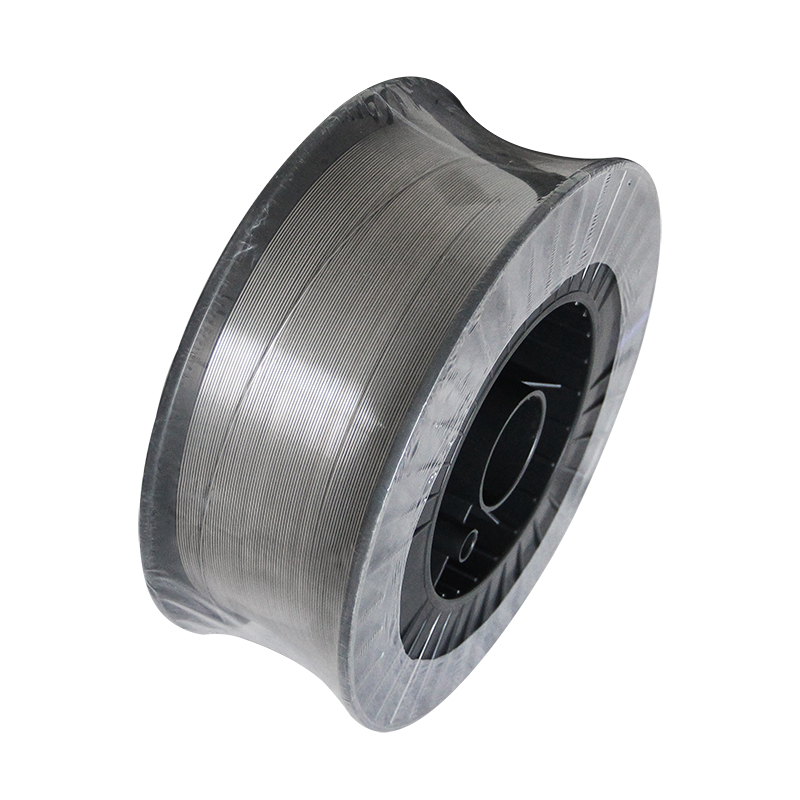

Kovar Wire | Kovar Wire Rod |

|

COMMERCIAL GRADE NAME |

SIZE MM |

FORMS Manufactured |

SPECIFICATIONS |

THERMAL CONDITIONS SURFACE FINISH |

|

Kovar (ASTM F15) |

0.1*32 |

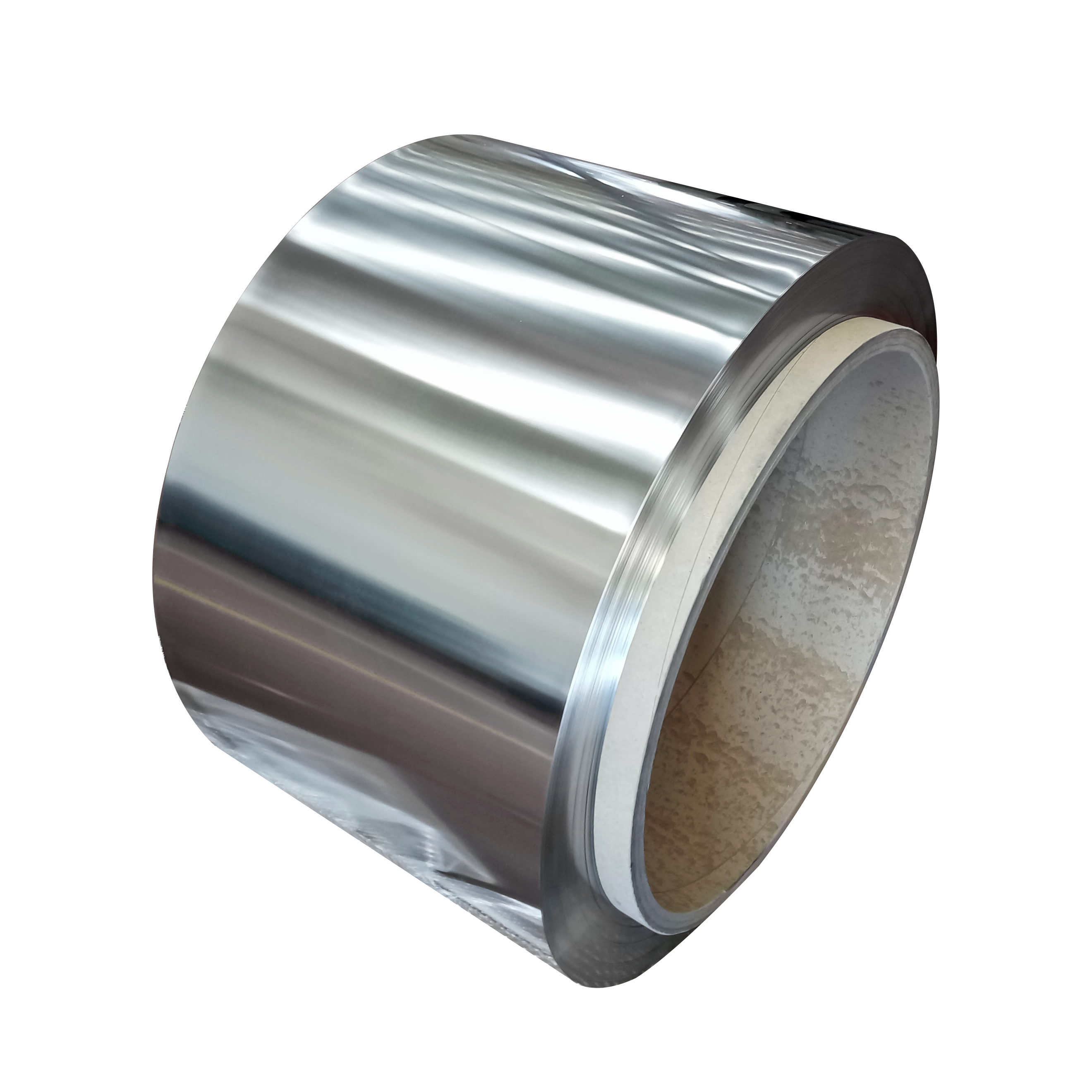

Coil |

ASTM F15 |

Hard |

|

Kovar (ASTM F15)

|

0.5*350.5 |

Coil |

ASTM F15 |

1/4Hard |

|

Kovar (ASTM F15)

|

0.7*118 |

Coil |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

Kovar (ASTM F15)

|

1.0*203 |

Coil |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

Kovar (ASTM F15)

|

1.2*200 |

Coil |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

Kovar (ASTM F15)

|

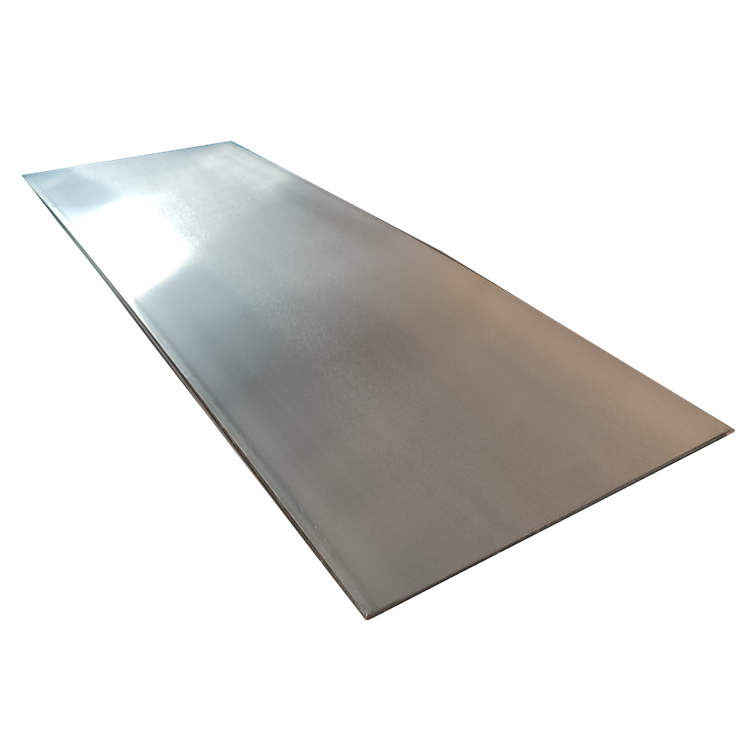

4.0*200*1200 |

Sheet |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

Kovar (ASTM F15)

|

1.5*280*1200 |

Sheet |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

Kovar (ASTM F15)

|

1.6*220 |

Sheet |

ASTM F15 |

Cold-Rolled (Bright Surface) |

|

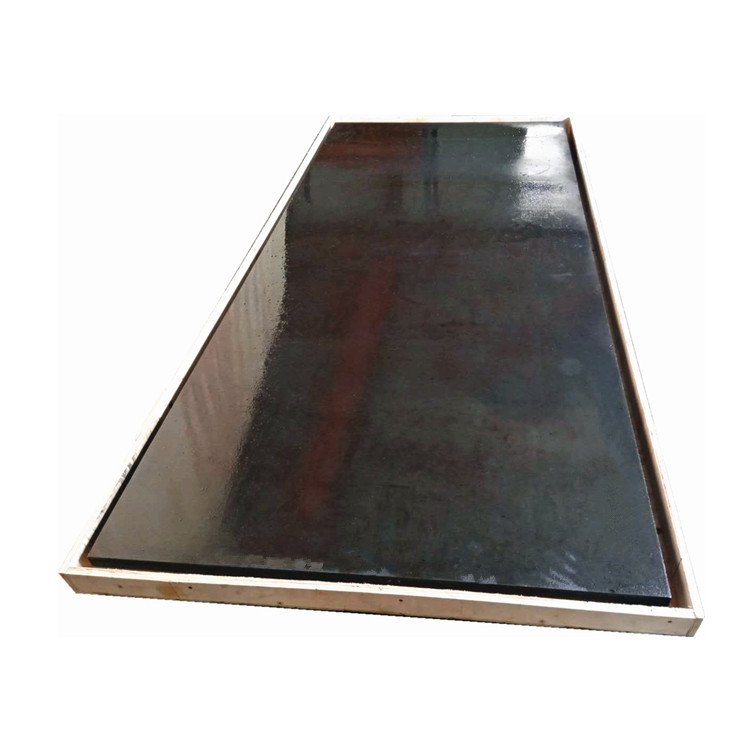

T9/10/11/12/13/22/24/27/32 * W220-1000*L500-6000 |

Sheet |

ASTM F15 |

Hot-Rolled (Black Surface) |

|

|

Kovar (ASTM F15)

|

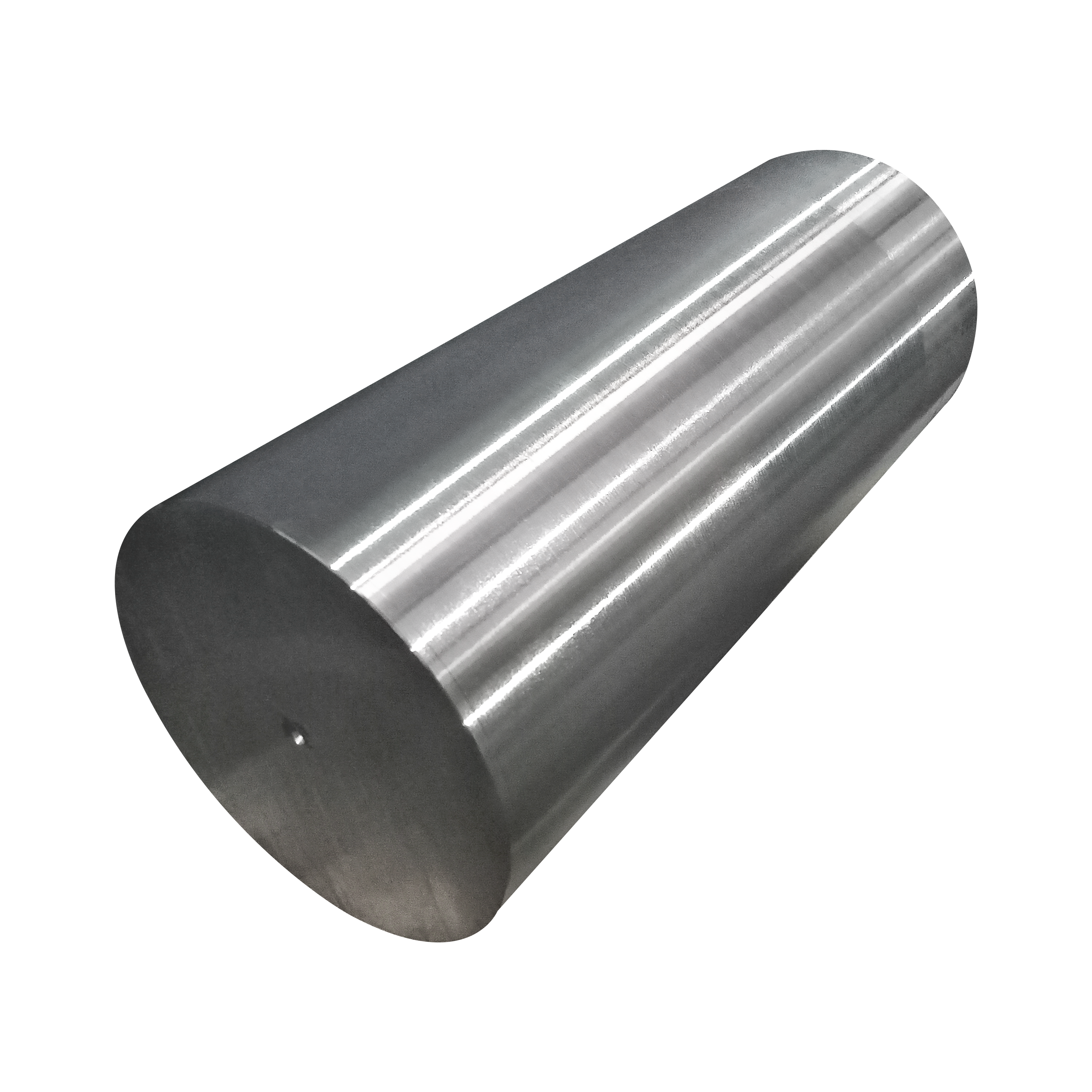

φ3 |

Cylinder |

ASTM F15 |

Cold-Drawn (Ground Surface) |

|

Kovar (ASTM F15) |

φ4 |

Cylinder |

ASTM F15 |

Cold-Drawn (Ground Surface) |

|

Kovar (ASTM F15) |

φ16 |

Cylinder |

ASTM F15 |

Hot-Rolled (Ground Surface) |

|

Kovar (ASTM F15) |

φ32 |

Cylinder |

ASTM F15 |

Forged Bar,Descaled |

|

Kovar (ASTM F15) |

φ60 |

Cylinder |

ASTM F15 |

Forged Bar,Descaled |

|

Kovar (ASTM F15) |

φ75 |

Cylinder |

ASTM F15 |

Forged Bar,Descaled |

|

Kovar (ASTM F15) |

φ80 |

Cylinder |

ASTM F15 |

Forged Bar,Descaled |

XAGY Advantages

1. High-qulity product

- ISO9001:2008 International Quality System Certification.

- With advanced equipments: VIMF, Induction Furnace, ESR Furnace ect.

- Strict Quality-testing System.

2. Strong R & D Strength

- 40,000㎡ production base.

- 60+ R & D team members, with rich customization experience.

- A good assortment of alloy to choose.

3. Efficient delivery

- Flexible transport means, very convenient.

- Tailor a suitable transport plan.

4. Good service

- We provide online service, information feedback within 24 hours.

- Professional team to provide remote technical advice and guidance.

Contact XAGY

Xi'an Gangyan Special Alloy Co., Ltd.

Hotline: 0086-29-33669103

Fax: 0086-29-33698670

Email: sales@xagy.cn

Add.: No. 88 East of Century Avenue, XianYang, Shaanxi, China. P.C.712046

Purchase:Control Expansion alloy ASTM F15 Kovar

- *Contact person:

- Mobile phone:

- Company name:

- *Email:

- *Purchase intention:

-

*Verification code: