-

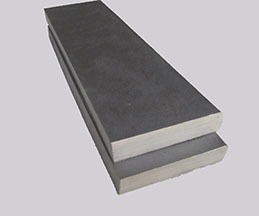

Alloy 42

Alloy 42,ASTM F30,UNS k94100,(Fe-42Ni) ,Chinese 4J42 42 Alloy, a low expansion alloy, is very similar to Invar 36 with a slightly different Coefficient of Thermal Expansion. This nickel-iron alloy is ideal forlid, lead frames, stencil/etching, telecommunications and aircraft industry, offering a more affordable alternative to Kovar when a tight seal is not required. Forms: Sheet/Plate, Bar/Rod/Wire/Coil,Capillary/Pipe/TubeMore +

- [Latest News]The New Products---CuNiSn Alloy2017.07.19 15:44

- This new steel alloy can provide high-elastic and High strenght .?it is has been used for applications where?used in the manufacture of relay, potentiometer, switch, plug-ins, lead frame, chemical industry and Marine parts, fasteners, ?instruments of ?the elastic element of the transducer , etc. Initial manufacturing is already underway and material is available upon request at different sheet thicknesses (from 0.04 to 0.8mm) for testing and prototyping purposes. Please call 86-29-33669103 or Email :sales@xagy.cn for additional information.

- read(33)

- [Industry News]Super Invar 32-52017.06.21 14:28

- Super Invar 32-5, a magnetic, austenitic, solid solution alloy containing iron, nickel, and cobalt, is designed to provide minimum thermal expansion at room temperatures. This alloy also exhibits austenite stability to service temperature at least -67°F and thermal expansion properties less than those of Invar 36 alloy (36% nickel-iron) when used in the -67/203& deg;F (-55/95°C) temperature range.

- read(136)

- [Industry News]Vacuum Induction Melting2017.05.19 16:21

- Vacuum induction melting (VIM) utilizes electric currents to melt metal within a vacuum. The first prototype was developed in 1920. One of the only ways to induce a current within a conductor is through electromagnetic induction. Electromagnetic induction induces eddy currents within conductors by changing the magnetic field. Eddy currents create heating effects to melt the metal. Vacuum induction melting has been used in both the aerospace and nuclear industries.

- read(227)

- [Industry News]Metallurgy of the Electroslag Remelting Process2017.05.05 15:07

- Whereas VAR needs vacuum for refining, in ESR the consumable electrode is dipped into a pool of slag in a water-cooled mold. An electric current (usually AC) passes through the slag, between the electrode and the ingot being formed and superheats the slag so that drops of metal are melted from the electrode. They travel through the slag to the bottom of the water-cooled mold where they solidify. The slag pool is carried upwards as the ingot forms. The new ingot of refined material builds up slowly from the bottom of the mold. It is homogeneous, directionally solidified and free from the central unsoundness that can occur in conventionally cast ingots as they solidify from the outside inwards. Generally the ESR process offers very high, consistent, and predictable product quality. Finely controlled solidification improves soundness and structural integrity. Ingot surface quality is improved by the formation of a solidified thin slag skin between ingot and mold wall during the remelting operation. This is why ESR is recognized as the preferred production method for high-performance superalloys that are used today in industries such as aerospace and nuclear engineering as well as for heavy forgings. Ingots are obtained with purity levels that were unheard of some years ago. Other branches of engineering are following the examples of the “high-tech” pacesetters and insist on new, high purity levels that can be obtained from ESR with the latest, most sophisticated equipment.

- read(92)

- [Industry News]Ni-span alloy c-9022017.03.13 16:20

- Ni-Span c902,AMS 5225,UNS N09902, (Ni42CrTiAl),Chinese 3J53 A precipitation hardenable Nickel-Iron-Chromium alloy having outstanding controllable thermoelastic coefficient characteristics and excellent oxidation resistance in high temperature atmospheres. The alloy can be processed to have a constant modulus of elasticity at temperatures ranging from -45 to +65 ℃(-50 to +150℉).

- read(220)

- [Industry News]What is a magnetic shield?2017.02.09 14:32

- First, one important point must be clear: Magnetic shielding does not block a magnetic field. No material can stop the lines of flux from traveling from a magnet's North pole to it's South pole. The field can, however, be redirected. ...

- read(166)

- [Industry News]Glass-to-metal sealing in vacuum industry2017.01.05 14:38

- Glass-to-metal sealing structure is commonly used in vacuum system, which requires air tightness and a certain intensity, baking resistance and certain electric insulation resistance. Glass-to-metal seal types are commonly divided into three parts: (1) matching sealing; (2) non-matching sealing; (3) transition sealing.

- read(44)

- [Industry News]Compression Seals and Matched seals2016.12.30 14:13

- If a higher cycle range is needed, you should consider Kovar' Matched Seals. A fundamental glass sealing process is used to manufacture glass seals in which the kovar metal thermal expansion coefficient matches the glass thermal expansion coefficient. The outcome is a highly effective hermetic seal.

- read(30)

- [Industry News]Vickers Hardness2016.12.23 14:23

- The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe the questioned material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests.

- read(41)

- [Industry News]Soft magnetic material2016.12.19 14:37

- Soft magnetic material includes a wide variety of nickel-iron and nickel-cobalt soft magnetic alloys and pure iron for high performance components requiring high initial and maximum permeability coupled with ease of fabrication.

- read(57)

- [Industry News]What is the difference bewteen cold rolling and hot rolling2016.12.15 14:42

- Cold rolling is used to make smooth and accurate thin sheets of metal. As cold steel is harder than hot steel, cold steel mills need harder rolls and, the power required for cold rolling is greater than that for hot rolling.

- read(32)

- [Industry News]What is the advantage of hot rolling?2016.12.08 14:22

- The advantage of hot rolling is that it can be reduced in thickness much more easily. But the surfice finish and accuracy are not so good as those obtainable by cold rolling. The most general use of hot rolling, therefore, is for "breaking down"large ingots.

- read(23)

- [Industry News]The corrosion resistance of chromium was found by accident2016.11.29 14:35

- Addition of chromium imparts hardness, strength, wear resistance, heat resistance, and corrosion resistance to steels.

- read(16)

- [Industry News]The role of molybdeum in alloy steel2016.11.25 14:29

- Molybdenum, even in extremly small amounts, has considerable effect as an alloying element on the physical properties of steels. Molybdenum improves strength,hardenability, and wear resistance. Molybdenum steels are readily heat-treated, fo...

- read(19)

- [Industry News]Nickel-iron mumetal alloy2016.11.22 14:34

- Mumetal is a nickel–iron soft magnetic alloy with very high permeability suitable for shielding sensitive electronic equipment against static or low-frequency magnetic fields.

- read(56)

- [Industry News]Thermal Advantages of Ceramic-to-Metal Seals2016.11.18 14:44

- Ceramic-to-metal seals not only remain stable at extremely high and low temperatures, but they are able to withstand severe thermal shock and repeated thermal cycling. Ceramic functions as an excellent electrical insulator at very high temperatures, unlike glass, which conducts more electricity at elevated temperatures.

- read(22)

- [Industry News]Glass-to-metal seal2016.11.14 14:24

- Glass-to-metal seals are a very important element of the construction of vacuum tubes, electric discharge tubes, incandescent light bulbs, glass encapsulated semiconductor diodes, reed switches, pressure tight glass windows in metal cases, and metal or ceramic packages of electronic components.

- read(35)

- [Industry News]Stainless steel2016.11.01 14:28

- Has good corrosion resistance, especially in some different concentration and temperature of organic acid and inorganic acid, or in oxidizing medium has good corrosion resistance;Also has good mechanical properties, is more suitable for subsequent machining, and because the non-magnetic, is the best choice for plastic mould materials required non magnetic and high corrosion resistance.

- read(18)

- [Industry News]Fe-Al soft magnetic alloy2016.10.26 14:15

- Fe-Al alloys contain 6% to 16% aluminum, the rest elements is the iron. The alloys have high resistivity, lower density and higher hardness of soft magnetic alloy. This family of alloy is suitable for the special environment (such as ...

- read(50)

Related search

Hot spot focusing

XAGY provides excellent Kovar Alloy products

- Kovar Alloy, also know as ASTM F-15, NILO K, Per...

- 1Hiperco 50a with High saturation magentic induction

- 2The New Products---CuNiSn Alloy

- 3Welcome KYOCERA customers to our company

- 4GE Company's Representative Visited Our Factory

- 5XAGY provides excellent Kovar Alloy products

- 6The applications of stainless steel

- 7Israel Customer Visit Xi'an Gangyan

- 8How do you ensure the quality of the products?

- 9What products & sevices can XAGY offer?

- 10How do alloys behave?