Description

Alloy 52 is a 52% nickel-iron alloy developed for glass-to-metal seals for some of the soft glasses and some ceramics. Produced with good machining properties, it’s manufactured in a controlled environment under controlled conditions.

Application

Glass to metal seals for electronic tubes, automotive and industrial lamps, and specialty hermetic devices.

parameter

Cross Reference:

| Russia | USA | UK | Japan | France | Germany |

| 50H | FeNi50 | Nilo51 | NS-1 | N50 | Vacovit500 |

Typical chemistry:

| C | P | S | Mn | Si | Al | Ni | Fe |

| ≤ | |||||||

| 0.05 | 0.020 | 0.020 | 0.80 | 0.30 | 0.10 | 49.0-50.5 | BAL |

Physical Property:

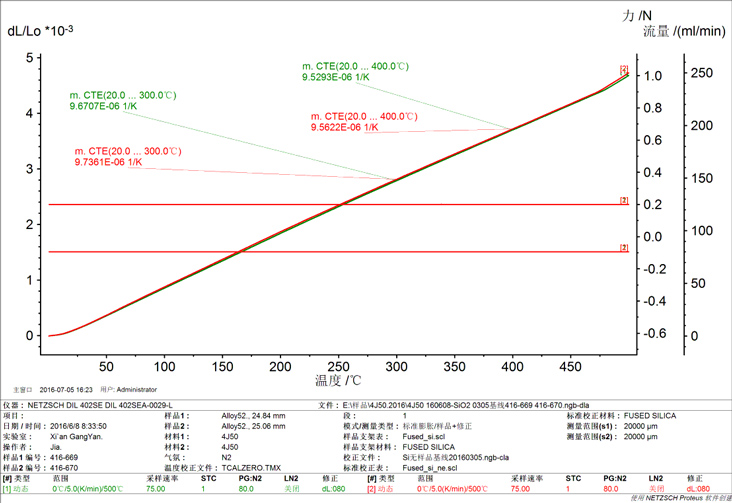

| Heat Treatment System of the Samples | Average Coefficient of Linear Expansion | ||

| 20-300°C | 20-400°C | 20-500°C | |

| To be heat treated at a temperature of 900±20℃ the hydrogen, hold for 1h, cool at a rate less than 5℃/min to 200℃ | 9.2-10.0 | 9.2-9.9 | |

Mean coefficient of linear expansion at different temperature, ā/(10-6/K):

Mechanical Properties:

| Elongation | % in 2 in. | 35 |

| Typical Hardness Ann | Rockwell HRB | 80 |

| Modules of Elasticity | ksi | 23 |

| MPa | 159 | |

| Yield Strength | ksi | 40 |

| MPa | 276 | |

| Tensile Strength | ksi | 80 |

| MPa | 552 |

Size Range

| Sheet | Thickness:0.10mm~3.50mm, width: ≤300mm |

| Plate | Thickness:3.5mm~40.0mm, width: ≤500mm |

| Round wire | Thickness:0.10mm~5.0mm |

| Flat Wire | Dia 0.5mm~Dia 5.0mm, length≤1000 |

| Rod | Dia 5.0mm~Dia 8.0mm, length≤2000 |

| Dia 8.0mm~Dia 32.0mm, length≤2500 | |

| Dia 32.0mm~Dia180.0mm, length≤1000 | |

| Capillary | OD 8.0mm~1.0mm,ID 0.1~8.0 length≤2500 |

| Pipe | OD 120mm~8.0mm,ID 8.0~129 length≤4000 |

Condition: (With max tolerance) cold rolled, cold drawn, hot rolled , hot forging ,peeled turned ,bright ,bright annealed

Global Hotline:0086-29-33669103

Global Hotline:0086-29-33669103

Kovar Alloy

Kovar Alloy Invar Alloy

Invar Alloy Hiperco 50A

Hiperco 50A HiperCo 27

HiperCo 27 Super Invar

Super Invar Ceramvar Alloy

Ceramvar Alloy 70HB

70HB Alloy 42

Alloy 42 Alloy 79

Alloy 79 65-Permalloy

65-Permalloy 12Alfenal

12Alfenal 430FR

430FR Alloy 46

Alloy 46 48 Alloy

48 Alloy 54K9X Alloy

54K9X Alloy Alloy 27

Alloy 27 Alloy 426

Alloy 426 Alloy79 Core

Alloy79 Core 316

316 304

304 Permalloy 80 Core

Permalloy 80 Core 77HXД Core

77HXД Core 1Cr18Ni9Ti

1Cr18Ni9Ti Alloy A286

Alloy A286 Inconel718

Inconel718 L605

L605 Alloy 50

Alloy 50 Comolloy

Comolloy VicalloyⅠ

VicalloyⅠ VicalloyⅡ

VicalloyⅡ Ni-span Alloy

Ni-span Alloy Elgiloy Alloy

Elgiloy Alloy Axle-centre Alloy

Axle-centre Alloy P6-Alloy

P6-Alloy Mutemp

Mutemp Permalloy 80/Mumetal

Permalloy 80/Mumetal 30HПД

30HПД